Express Tanks

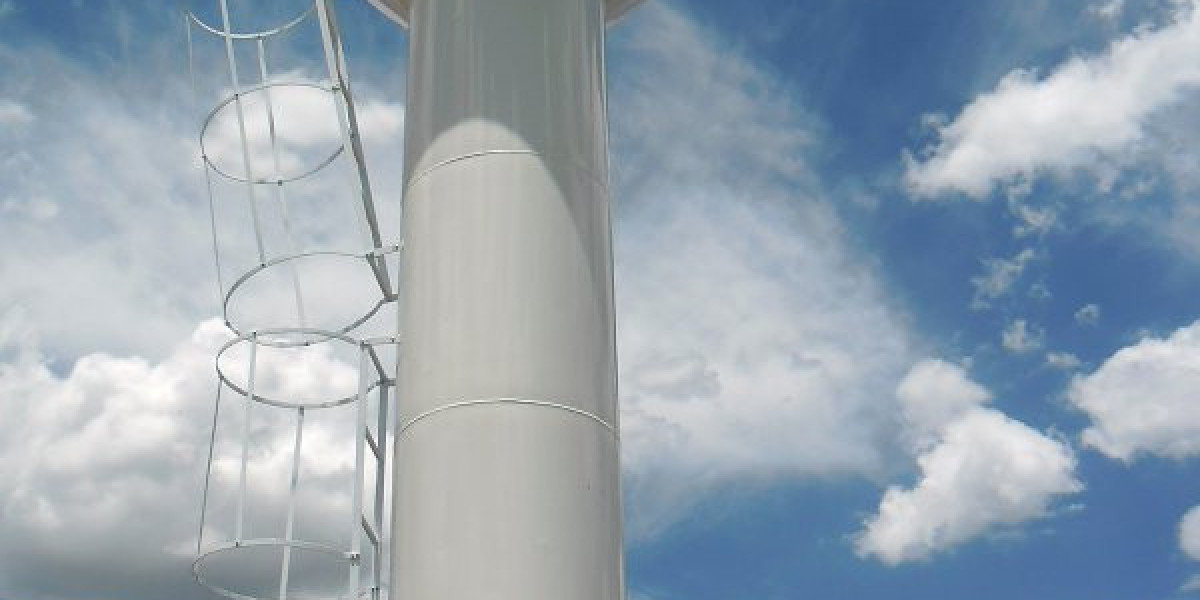

Express Tanks We are the by word in relation to reliable and sturdy stainless steel water storage tanks. Lightweight metal panels and heavy obligation galvanizing make Aquamate’s massive metal water tank shells perfectly suited to water storage. Aquamate’s tank panels are lined with a galvanized coating that’s 1.forty five ounces per sq. foot (G145) – the thickest advertised coating available on the market. By using light-weight thin-gauge metal panels, Aquamate’s steel water tanks have all the required power to withstand water, snow and seismic loads without the surplus material value.

En situaciones donde la superficie presenta irregularidades y se necesita una mayor resistencia de la lámina, ofrecemos una solución a través de la instalación de un material especial para el fondo, como el Geotextil No Tejido Geoditex.

Debido al componente P.V.C y la resina Epoxi Blanca se asegura la pulcritud de las aguas, además de aceptar una simple limpieza de estas. Esta parte se refiere a la edificación que mantiene la carga de los alzamientos del depósito agua. Están construidos en chapa con recubrimiento ProMag, una alternativa más respetuosa con el medio ambiente ya que usa menos zinc que los procesos de galvanizado convencionales. Con DeposSpain®, nos comprometemos a ofrecer soluciones de almacenaje de agua que no solo sean eficaces y prácticas, sino más bien asimismo respetuosas con el medio ambiente. Descarga fichas técnicas, hojas de seguridad, certificaciones, catálogos, manuales de empleo, etcétera.

Adventure Force Furia Del Dragón Pista Vence Al Dragón Color Azul

El acero inoxidable es más caro que el hierro colado o el acero galvanizado, pero es muy fuerte a la corrosión y la vida útil es larga. El aluminio es un material ligero, pero es menos fuerte a la presión que el acero. El polietileno de alta consistencia es resistente a la corrosión, pero no es adecuado para aplicaciones que necesitan altas temperaturas. El fibrocemento es un material de bajo valor, pero también es susceptible a la corrosión. Para finalizar, la fibra de vidrio es un material muy duradero que se puede usar para la construcción de tanques de almacenamiento de agua. Es un material ligero, resistente a la corrosión y no se observa afectado por los cambios de temperatura. Sin embargo, es un material muy caro y requiere una instalación cuidadosa para evitar la corrosión.

El mantenimiento periódico es fundamental para prolongar la vida útil de tu depósito y asegurar la calidad del agua. Incluye inspecciones regulares para detectar fugas o daños y métodos de limpieza para evitar la acumulación de sedimentos y la proliferación de algas. Este cuidado garantiza que el agua guardada continúe segura para su empleo. El sistema Ilurprelac está concebido para que sea el cliente quien haga el montaje del depósito con el mínimo de molestias y con una considerable ahorro en costes.

This gives you essentially the most dependable heat supply on your particular needs. When you want to rely on warmth to get the job carried out, you can depend on ProTherm Tubular Heating Elements to do it proper. The tubes are measured by their outside dimensions and their wall thickness. Infrastructure Projects – Rectangular tubes are utilized in bridges, platforms, and different large-scale infrastructure due to their high load-bearing capacity. The heater element requires a chilly part at each finish to keep the electrical terminals from overheating.

NSF/ANSI 61 Certified for Potable Water Use Tank Liner

As-welded (or electric-resistant welded [ERW]) – The as-welded technique of manufacturing metallic tubing involves rolling steel strips right into a tube and welding alongside the seam. This course of is more cost-effective than seamless manufacturing and allows for greater selection in dimensions and shapes. The weld seam can be a factor in purposes the place strain or corrosion resistance is important, but trendy welding techniques have significantly improved seam energy and integrity. As-welded tubing is extensively utilized in non-critical functions like common construction, fencing, and a few automotive elements. Aluminum – Aluminum rectangular tubing is a flexible and light-weight possibility generally utilized in varied industries. Its strength-to-weight ratio is right for structural purposes where weight reduction is essential, like in aerospace or automotive manufacturing.

Year "No Service Costs" Warranty

Environmentally safe and biodegradable, KoirMat™ is the preferred selection of erosion management specialists around the globe. This process enhances the tubing’s dimensional accuracy and produces a more uniform wall thickness. The DOM methodology results in elevated power, superior surface quality, and better concentricity than as-welded tubing. It’s generally utilized in high-precision functions corresponding to automotive elements, visualizá-lo hydraulic cylinders, and mechanical tubing, the place shut tolerances and clean surfaces are important.

Services

Additionally, gentle steel can be additional strengthened via galvanization, enhancing its resistance to corrosion and put on. Lightweight metal panels and heavy responsibility galvanizing make Aquamate’s massive metal water tank shells perfectly suited to water storage. Aquamate’s tank panels are lined with a galvanized coating that’s 1.forty five ounces per sq. foot (G145) – the thickest marketed coating on the market. By utilizing light-weight thin-gauge steel panels, Aquamate’s metal water tanks have all the required energy to resist water, snow and seismic hundreds with out the excess material price. Stainless Steel – Stainless metal rectangular tubing is very valued for its sturdiness and corrosion resistance, making it a best choice in environments prone to moisture or chemical substances.

The tubing can also be immune to corrosion, making it suitable for outdoor or harsh environments. It’s available in a range of sizes and thicknesses, catering to particular project requirements. The material’s malleability allows for straightforward shaping and becoming a member of, enhancing its suitability for complicated designs. Our steel water tanks can be found in 9 standard sizes, from 130″ to 512″ diameter, giving you a range of sizes and volumes to go properly with your residence, enterprise, ranch or farm’s necessities. Seamless (can be produced through extrusion) – The seamless technique of producing rectangular tubing involves extruding a strong metal billet right into a tube shape without welding. This course of creates tubing with uniform energy and smoothness, making it perfect for high-pressure applications and environments where reliability and precision are essential.